Following on from the insightful opinion piece from RIA Chief Executive Darren Caplan on HS2 which you can read here. We are diving into some of the more technical challenges facing high speed rolling stock, with an exploration of the impact of high speed travel on the pantograph-OLE interface from Dr. Pedro Antunes and Prof. João Pombo of The Institute of Railway Research, University of Huddersfield Centre of Excellence in Rolling Stock leads.

High-speed trains play a critical role in the socio-economic development of modern societies, breaking down barriers of distance and travel time. With globalization and economic growth, a significant increase on the demand for passenger and freight transportation is expected and the railway is a key player in worldwide transportation policies. As well as helping to address the problems of sustainability and decarbonisation, high-speed railways also offer a reliable and efficient transportation solution with recognized high levels of safety and comfort.

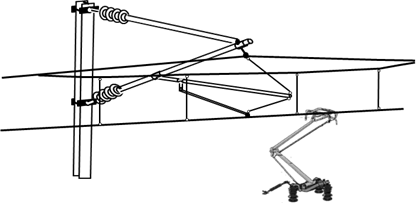

One crucial element for the reliable operation of high-speed trains concerns the energy collection system and its ability to supply a proper and uninterrupted amount of electric energy to power the traction vehicles and maintain the required service speed. The train energy collection is ensured through the pantograph-OLE (Overhead Line Equipment) interface. The OLE, also known as the catenary, is a structure composed of a set of suspended wires and supporting elements that run along the track and carry electric current to the train as required. This current is collected by the pantograph, which is normally mounted on the roof of the train, via sliding contact between the OLE contact wire and contact strips on the pantograph head. It is of the utmost importance to assure that this contact remains uninterrupted and is as stable as possible. Failure to do so, breaks the power supply to the trains, compromising their operational performance. Contact losses also lead to arcing between the contacting elements resulting in high electro-mechanical wear and other risks. Therefore, the interaction between the pantograph and the OLE needs to be carefully addressed in order to avoid service disruptions, incidents and higher maintenance costs.

Figure 1. The pantograph-OLE system Figure 2. Arcing between the pantograph and OLE

The pantograph plays an important role in the current collection system as it is required to quickly and efficiently react to the contact conditions, assuring compliance with tight functional requirements defined in standards and regulations. OLE design is also very important in order to improve interaction performance and reduce the life-cycle-costs of the equipments. In high-speed rail operations, a higher dynamic response of the pantograph is required and, most often, the pantograph and the OLE are paired and fine-tuned to obtain the best contact performance. To achieve this, it is essential to have a clear understanding of the dynamic behaviour of both the pantograph and catenary as well as the interaction between them. This is particularly challenging at high speed as the pantograph needs to react very rapidly to changes in the wire position. The current demands can also be very high for high speed trains.

The UKRRIN Centre of Excellence in Rolling Stock is addressing these challenges and providing support to the railway industry by developing tools to model the pantograph catenary interaction. By employing and developing state-of-the-art, reliable and validated computational tools, it is possible to study a wide range of scenarios and understand the dynamic behaviour of the systems involved. These tools enable to assess the contact quality between a specified pantograph and an OLE system, evaluate the impact of design changes or failure modes, de-risk new solutions and reach optimised designs. Computational studies can be performed in a much faster and less costly manner, avoiding physical implementations and expensive line tests.

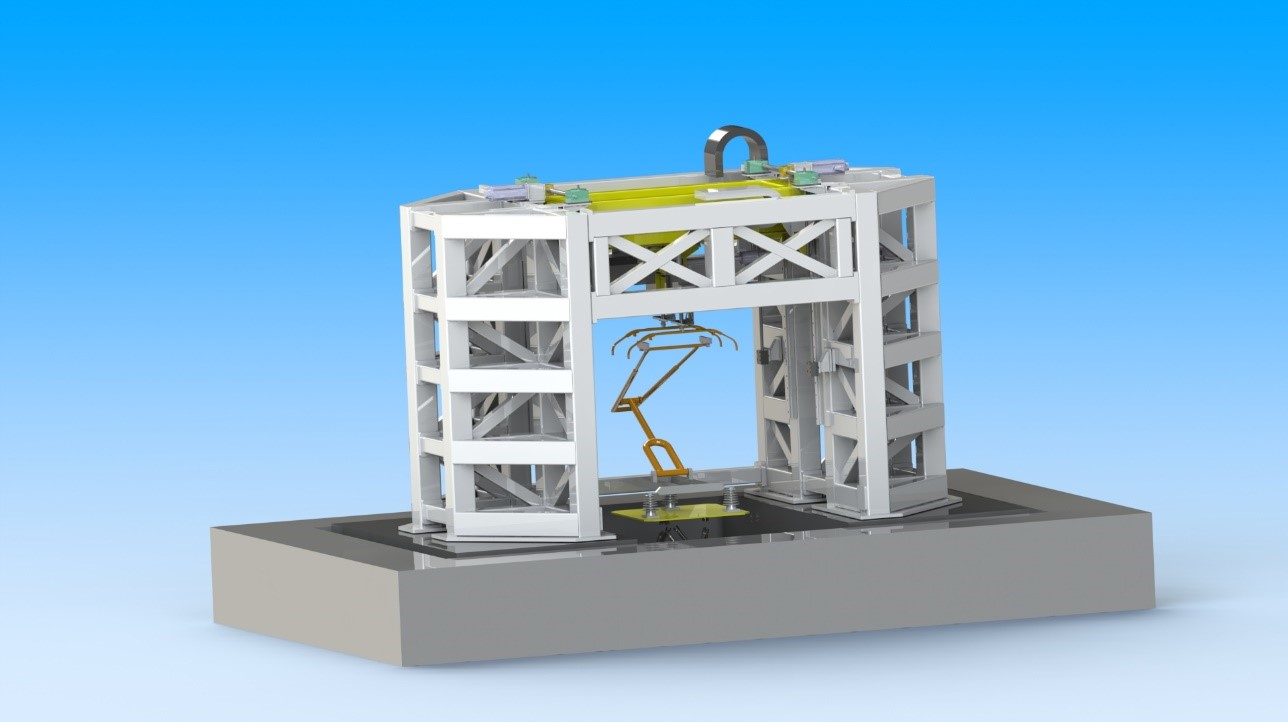

The Centre of Excellence in Rolling Stock capability is soon to be further bolstered through the recently commissioned £3.5M pantograph-catenary dynamics test rig, to be fully operation in April 2020. This world class facility is designed to be flexible and consider several modes of operation such as pantograph operation testing at 400 km/h, inclusion of carbody movements, and Hardware-in-the-Loop simulation in which actuators are placed over the pantograph head to replicate the behaviour of realistic OLE numerical models. Together with its expertise, this test facility will enable the UKRRIN Centre of Excellence in Rolling Stock to further support the industry not only in its current needs but also in future challenges, de-risking technology development and contributing to increase the competitiveness of railway transportation.

-ENDS-

Read more from this blog series here: